After several late-night fabrication sessions, Son of Pendragon was ready to go. I had no time for practice shots, so this would be interesting.

The firing line on setup day. Gourdinator had not arrived by the time we left. Only four machines this year, unfortunately.

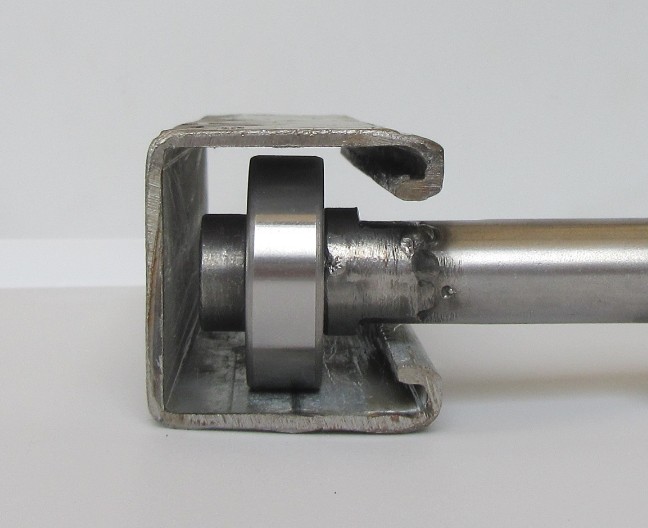

SoP ready to go. I couldn’t figure out a cocking mechanism in time, so the counterweight arm was lifted manually and the weights added via ladder. Definitely not the ideal solution as far as safety is concerned, which we will have to change for next year.

“Gladiator Gourd Girls”, a traditional trebuchet made by Girl Scouts.

“Bad Wolf”, an onager (powered by twisted ropes).

And of course Gourdinator, a floating-arm-trebuchet that has competed every year.

SoP won its division with a shot of 447 feet (with a 1.4 lb. pumpkin). That works out to almost 5 feet per pound of counterweight (compared to about the 1.5:1 ratio Ballistikraft had). Can we improve on that? Find out next year!

Video footage to follow.